The fourteenth edition of the WCM Summer School focused on an extremely current and complex case study. Case owners KMWE and Brainport Industries presented the participants with a challenge concerning remanufacturing and circular supply chain collaboration. According to Summer School Director Jan Braaksma, the topic offers ample opportunities for innovation in practice. “The case owners can directly incorporate the students’ ideas into their planning.”

Edward Voncken, CEO of KMWE, agrees. “What the students present to us really helps us look at things from the outside in. I’m very impressed that the participants were able to get to the heart of this complex challenge so quickly and also find solutions for it.”

“Edward Voncken: ‘Remanufacturing can be a win-win for everyone.’”

Smarter, more sustainable, and more efficient

The challenge that the teams will tackle centers around the desire to work smarter, more sustainably, and more efficiently with components within the high-tech supply chain. KMWE, a supplier of precision parts for industries such as semiconductors and aerospace, sees opportunities for remanufacturing: the reuse of used or obsolete components. This not only saves costs but also reuses scarce materials and reduces the environmental footprint. Brainport Industries, the high-tech supply chain network from the Eindhoven region, is collaborating with KMWE to establish a triage center. Director John Blankendaal: “Within the high-tech chain, we are looking for solutions within the circular business program Semicon to work more sustainably, and remanufacturing is one way to do that. By bringing this case forward, we hope to gather valuable input.”

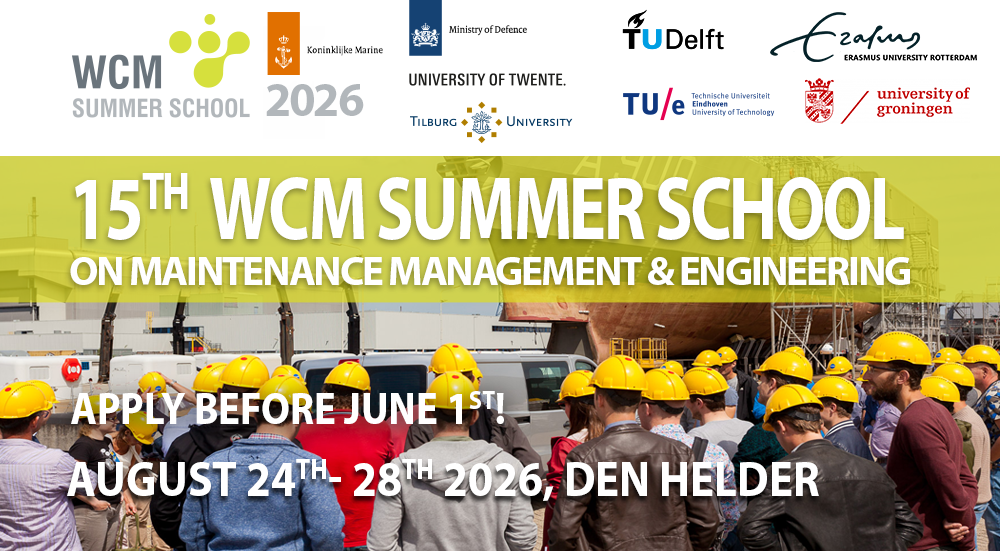

Annual Study Week

The WCM Summer School is an annual study week centered around smart maintenance, designed for young professionals with a maximum of ten years of work experience and for final-year bachelor’s and master’s students. During the week, participants attend substantive lectures and interactive workshops, delivered by various universities. The Ministry of Defence contributes with a leadership training in a military setting. The Summer School is organized by World Class Maintenance in collaboration with seven Dutch universities and the Ministry of Defence, and is open to both members and non-members of WCM.

Tricky questions

The central task for this summer is to develop a business case for a triage center – a physical and organizational hub where returned modules are assessed, diagnosed, and repurposed for use. While it sounds logical, in practice it’s anything but simple. Many components contain subcomponents from multiple suppliers. This raises complex questions. Who is responsible for what? How do you share information without risking intellectual property (IP)? How do you allocate risks, costs, and revenues? And at least as important: does the end-customer accept a refurbished module – even if it’s quicker to deliver and comes with a warranty?

On top of that, there’s the unpredictability: no one knows exactly which components will arrive at what time. Not all parts are economically or technically feasible to refurbish. Therefore, a rapid diagnosis at the outset is crucial.

Mixed teams

The WCM Summer School is taking place this year on the parade ground at ’t Harde. Participants are coming from technical companies, Defence, and universities. They work in mixed teams for a week on the case. Jasmijn van Althuis (Verebus Engineering) is one of them. “A colleague of mine participated last year, that’s how I found out about the Summer School. It was a really fun week, and I particularly enjoyed seeing all the different skills in the team utilized in the right roles. I found the company visit at KMWE surprisingly fun. We saw some really cool things.”

Innovation is needed

Before the teams present their pitches, WCM operational director Paul van Kempen provides a brief introduction. He outlines the broader context of maintenance and asset management in which the Summer School fits. “The gap between maintenance demand and maintenance capacity is only growing. Innovation must bring the solution.” He highlights WCM’s role as a network organization and issues a call to action: “Join us and get involved.” Braaksma then reflects on the week of lectures and workshops covering topics such as Design for Remanufacturing, Sustainable Asset Management, Strategic Decision Making, and leadership. He then explains the central questions of the case: what business model fits the triage center, how do you regulate governance and IP, and what does a workable legal framework look like?”

The team presentations

The jury this year consists of Giacomo Barbieri (University of Twente), Paul van Kempen (WCM), John Blankendaal (Brainport Industries), Edward Voncken and Jochem Langendonk from KMWE. They assess the pitches based on creativity, realism, and persuasive power. Group one kicks off with the idea of setting up the triage center also as an R&D Center, where systematic Root Cause Analysis takes place. This way, in addition to an operational function, a knowledge function is also created. Group two comes up with a surprising marketplace construction. After diagnosis, a component can be offered on a platform. The original supplier gets the chance to repurchase it, remanufacture it, and bring it back into the supply chain.

The third group opts for speed: a pitstop model, with diagnostic equipment from multiple OEM’s and suppliers present. Through direct analysis and rapid triage, the turnaround time is reduced. Group four develops a model in which risks, costs, and revenues are mapped out in advance. Based on this, they propose a key to allocate revenues according to risk. Team five establishes a workable step-by-step plan that is also applicable to other OEM’s. In their proposal, a pre-diagnosis takes place with the supplier, only after which the module is sent to the triage center. Group six focuses on financial feasibility and the inflow of modules. Their idea: leverage the existing backlog of used components currently lying in storage in Weert.

Strengths and weaknesses

’Each team has its strengths and weaknesses,’ concludes Braaksma after the presentations. ‘But together, it offers beautiful solutions.’

During the break, the audience votes for their favorite. The public prize goes to group two, with praise from the audience for ‘the simple way in which ownership is handled’ and the fact that the idea is applicable in other sectors. Group five comes in third, and group one second. Then, the jury announces its choice. Voncken emphasizes first that ‘the summation of all elements of all teams’ is the winner for him. However, the jury designates team two as the overall winner. ‘The solution is applicable in multiple markets, is based on existing examples, and was also presented very well.’ According to the jury, the proposal combines economic benefits, circular profit, knowledge Sharing, and improved tracking for OEM’s.”

Highlighting the win-win

After the certificate presentation, there’s time for a closing drinks reception. Voncken says he’s pleased with the diverse perspectives. “It’s commendable to get to the core of the issue in such a short time. Now it’s up to us, as part of the supply chain, to convince our OEM’s that remanufacturing is a win-win for everyone. It’s not a competition; we must do it together, for the benefit of all and for the environment.” Blankendaal confirms this. “The jury’s choice of team two was unanimous, although each team had something good. In that light, I’d like to reiterate the marketplace idea. Very well conceived. We’ll gather and analyze all input over the coming weeks with KMWE and WCM, and then determine what we’ll pursue further.”

Participant Bodhi Buurman of Swarco – a member of the winning team – succinctly captures the enthusiasm: ‘Of course, we said beforehand that we would win, but that we would win both prizes, we didn’t see coming. Everyone in the team contributed their part, and that’s also the most important thing I learned during this week: it’s important to know the qualities of your team members so that you can then optimally utilize them.’”